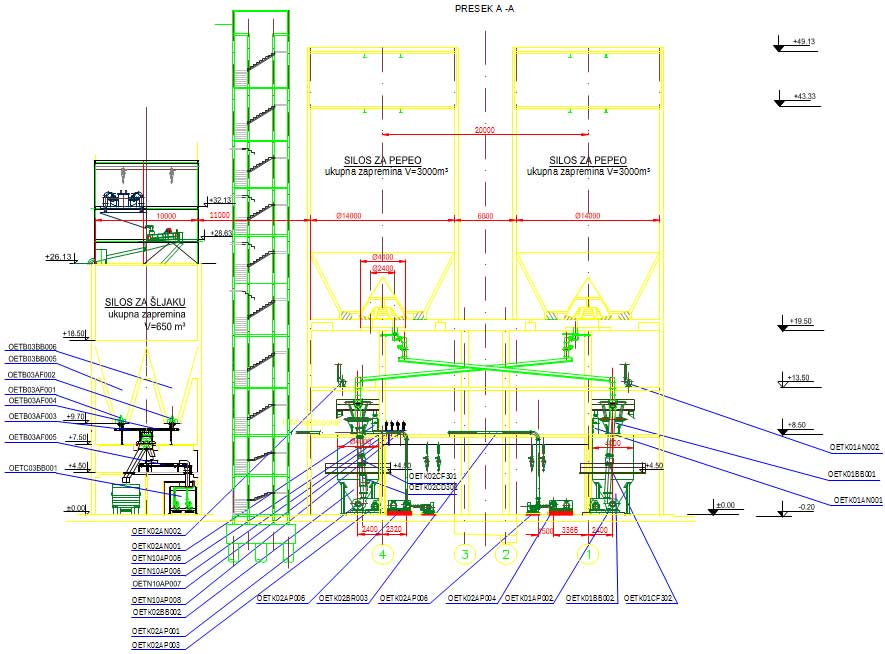

The assignments of the Department for the preparation of mineral ores and designing are development and innovative research, characterization of the products of the preparation process of mineral ores, laboratory semi-industrial and industrial testing of the enrichment and refi ning of mineral and waste ores, purifi cation of waste waters, improvement and development of more advanced technological solutions, designing of facilities for PMO, hydro-transport systems, infrastructure and logistical facilities, depots of fl otation tailings, fl ying and bottom ash and industrial waste materials. A part of these assignments are the technical control and receipt of facilities, guarantee and operational examinations of technical and technological performances of facilities, monitoring of depots and tailing depots, production of project investment-technical documentation for mining, energy and industrial facilities, machine and electro energetic installations and facilities, construction objects tall and low, bridges, steel and concrete constructions, climate and heating systems, hydro-technical facilities, pipelines and sewage, artifi cial rain systems etc.